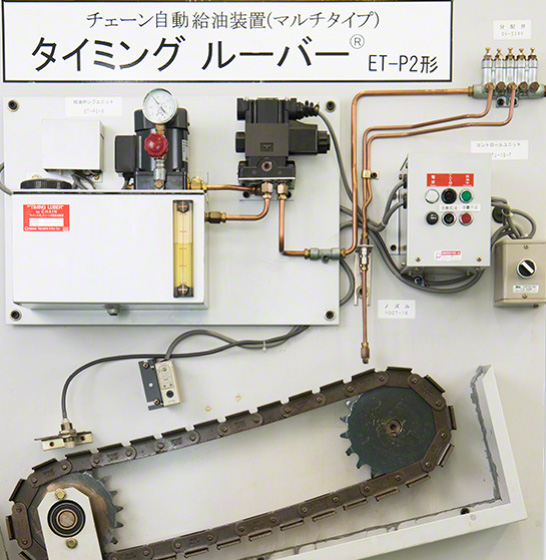

Chain Automatic Oiling Device

Timing Luber ET-P2

(Multi/General purpose type)

Features

- You can expect longer operating life without trouble, since it does not touch the chain.

- One device can correspond to plural chains.

- It can correspond to faster chain speed, since plural places can be oiled at once.

- It can correspond to large-sized plants, since maximum piping capacity is 30m.

- Oiling is possible from all directions (vertical and horizontal).

- Management is easy, since the power source is electricity only.

- Transfer and maintenance is easy and installation space is not limited, since the device is a wall hanging type and built into the panel.

General Drawing

Lubrication Specification

| Lubrication Method | Timing detection sensor catches the chain link in operation and sends a signal to the distribution valve. Receiving the signal, oil pre-accumulated within the distribution valve injects instantly. Oil is supplied to the chain lubrication point through the nozzle. |

|---|---|

| Oiling Quantity | 0.1–1.0㎤ per place/time (step-less oil adjustment is possible) |

| Oiling Capacity | Up to 30 places/time. However, differences may occur according to total piping extension and installation environment condition, etc. |

| Kinematic Viscosity Range | 20–1000㎟/s |

| Timing Tracking Capability | As a standard, transit time of the link is 1.5 seconds or more. However, if plural places can be oiled at once, it can correspond to the speed accordingly. |

| Piping Capacity |

Main pipe (Φ 8✕6) = up to 30m Branch pipe (Φ 6✕4) = up to 0.5m |

| Timing Detection Sensor | Proximity switch (optoelectronic switch, limit switch, etc. can also be selected according to installation environment) |

| Control (Control Unit) |

Oiling time exclusive type – Oiling time for all links is set in advance, and oiling will automatically stop after the predetermined set time elapses. Oiling time accumulation type (option) – Only oiling time is counter accumulated. |

Product Information page